The demand for efficient and durable shade net solutions has led to a surge in the development of advanced fabrication machines. These high-performance systems are designed to generate shade nets with exceptional strength, UV resistance, and longevity. Utilizing cutting-edge methods, these machines can efficiently handle a wide range of materials, including nylon, to produce shade nets of various dimensions.

Key features of high-performance shade net making machines include automated operation, heavy-duty construction, and intuitive interfaces. These machines often incorporate intelligent control systems to ensure reliable production output and minimize material waste.

The use of high-performance shade net making machines has revolutionized the industry, enabling manufacturers to increase their production capacity, reduce manufacturing costs, and deliver high-quality shade nets that meet the evolving needs of various sectors, such as agriculture, construction, and landscaping.

Robust Plastic Net Machines for Every Need

Whether you're producing fishing nets, bird netting, or other purposes, a durable plastic net machine is an essential tool. These machines are built to withstand the rigors of constant operation and produce high-quality nets that are both resilient and adaptable. A wide range of models is available, each with its own set of capabilities to address the specific needs of your business.

- Consider the type of net you'll be making.

- Establish the desired mesh size and material thickness.

- Explore different machine brands and models to find the best fit for your budget and specifications.

With a little here planning, you can find the perfect durable plastic net machine to enhance your productivity and production.

Green Net Manufacturing Solutions

The industry of net manufacturing is rapidly evolving, driven by a growing demand for sustainable solutions. Green net manufacturing provides a effective alternative to traditional methods, reducing the environmental impact. By implementing cutting-edge technologies and pioneering materials, we can manufacture high-quality nets that are both resilient and environmentally responsible.

- Features of Green Net Manufacturing Solutions:

- Reduced Carbon Footprint

- Conserved Natural Resources

- Improved Product Durability

- Elevated Consumer Satisfaction

Renowned Manufacturer of Shade Nets

We are a prominent supplier of high-quality shade nets. Our nets are designed to provide superior protection from the elements. We utilize advanced technologies and top-grade materials to provide durability and functionality.

Our solutions are extensively used in a number of applications, including:

* Gardening

* Development

* Hardscaping

* Industrial

We have become committed to providing customers with reliable products and outstanding customer service.

Cutting-Edge Shade Net Production Technology

The production of shade nets has undergone a remarkable transformation in recent years, driven by cutting-edge technologies designed to optimize efficiency and durability. From precision weaving machines to advanced fabric treatment processes, the industry is embracing innovation to manufacture shade nets that are resilient and longer-lasting. This emphasis on technological advancement has led to a wide range of shade net options, catering to the specific needs of various applications.

Adjustable Shade Net Weaving Machines

In the realm of shade net production, versatility reigns supreme. This is where customizable shade net weaving machines step in, offering unparalleled control over the mesh structure and final product. These cutting-edge machines permit manufacturers to adjust various parameters, such as fiber thickness, weave pattern, and shade density, to meet the particular needs of their customers.

The benefits of utilizing customizable shade net weaving machines are numerous. They enable the creation of shade nets with accurately controlled UV protection, catering to a variety of applications, from agriculture to construction.

- Moreover, these machines often incorporate digital control systems for enhanced precision.

- Consequently, manufacturers can realize consistent product quality and reduce manual labor requirements.

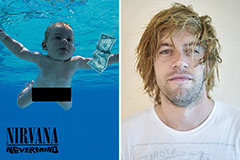

Spencer Elden Then & Now!

Spencer Elden Then & Now! Kirk Cameron Then & Now!

Kirk Cameron Then & Now! Charlie Korsmo Then & Now!

Charlie Korsmo Then & Now! Barry Watson Then & Now!

Barry Watson Then & Now! Freddie Prinze Jr. Then & Now!

Freddie Prinze Jr. Then & Now!